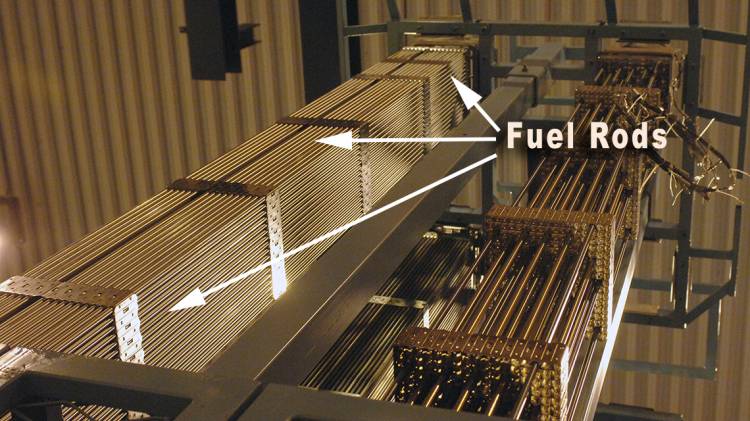

The China Atomic Energy Authority (CAEA) informed the IAEA yesterday that a minor fuel cladding failure ?had occurred at the Taishan Nuclear Power Plant. What are fuel cladding failures, and what do they mean for safety? Read our explainer to find out.

Nuclear power plants are designed with multiple back-up and diverse safety systems as part of an approach to safety, called “defence-in-depth”. This means there are multiple, redundant safety systems designed to prevent any accidental radioactive release. In addition, there are multiple barriers, including the primary reactor coolant system or primary circuit and a single or double containment building, which are designed to prevent any radioactive release to the environment.

Therefore, an increase in the level of radioactivity in a primary reactor coolant is different from a radioactive leak. The primary circuit is inside the containment and there are several further barriers to prevent releases of radioactivity to the environment.